M32 6 Speed manual transmission

Bearing failure on the M32 gearbox is very common.

Typically you will notice a whining noise when cruising on the motorway in 6th gear. The whining will come and go as you press and release the accelerator. When the bearings wear even more, the gearstick will begin to move as you press and release the clutch in first gear.

In our experience, just one bearing fails.

Failed bearing is at the top of the photo

Excessive play and loose rollers

The bearing becomes pitted due to metal fatigue

Replacement of this bearing will usually rectify the issues with gearstick movement and whining.

Background information on the M32 gearbox

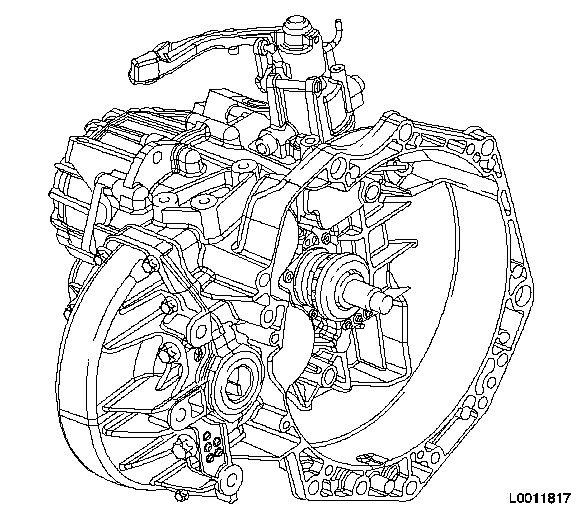

The M32 is a 6-speed manual transmission. This manual transmission is an all-synchromesh 3-shaft transmission.

This 3-shaft transmission has the following advantages:

- Compact construction

- Improved smooth-running performance

- Better shift quality

- High torque transmission

- Low weight

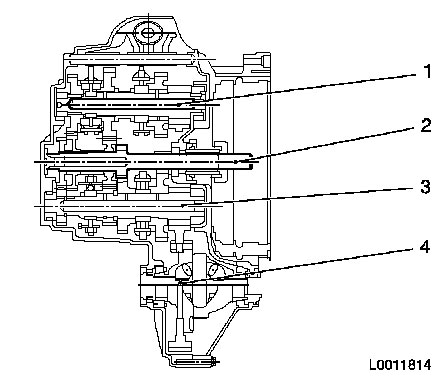

Structure of the manual transmission Location of the shafts The following cross-sectional diagram shows the location of the respective shafts in the M32 transmission, as per the 3-shaft principle.

Structure of the manual transmission

Location of the shafts

The following cross-sectional diagram shows the location of the respective shafts in the M32 transmission, as per the 3-shaft principle.

- Upper main shaft

- Input shaft

- Lower main shaft

- Differential gear

In this transmission angular cone bearings are used for all shafts. These bearings require a certain amount of play and pre-tension. The required amount of bearing play and pre-tension is achieved at the production stage by using shims under the angular cone bearing in the transmission housing.

Location of gearwheels

This diagram shows the location of the gearwheels on the respective shaft.

- Lower main shaft

- 1st gear gearwheel

- 2nd gear gearwheel

- 5th gear gearwheel

- 6th gear gearwheel

- Input shaft with 1st/2nd gear

- 3rd/5th gear gearwheel

- 6th gear gearwheel

- 4th gear gearwheel

- Upper main shaft

- 4th gear gearwheel

- Reverse gear gearwheel

- 3rd gear gearwheel

One particular advantage of this 3-shaft transmission is that on the input shaft, the 3rd gear gearwheel is also used for 5th gear.

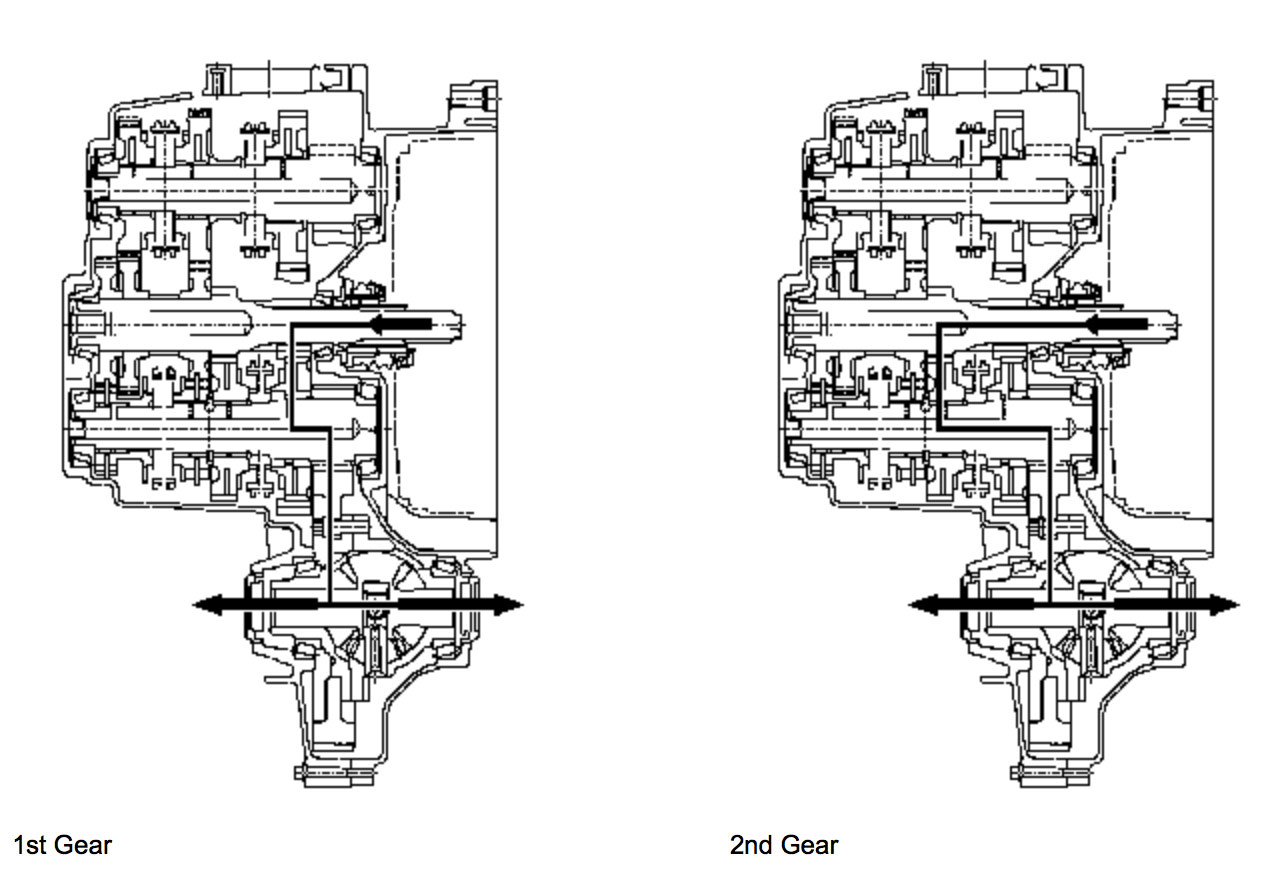

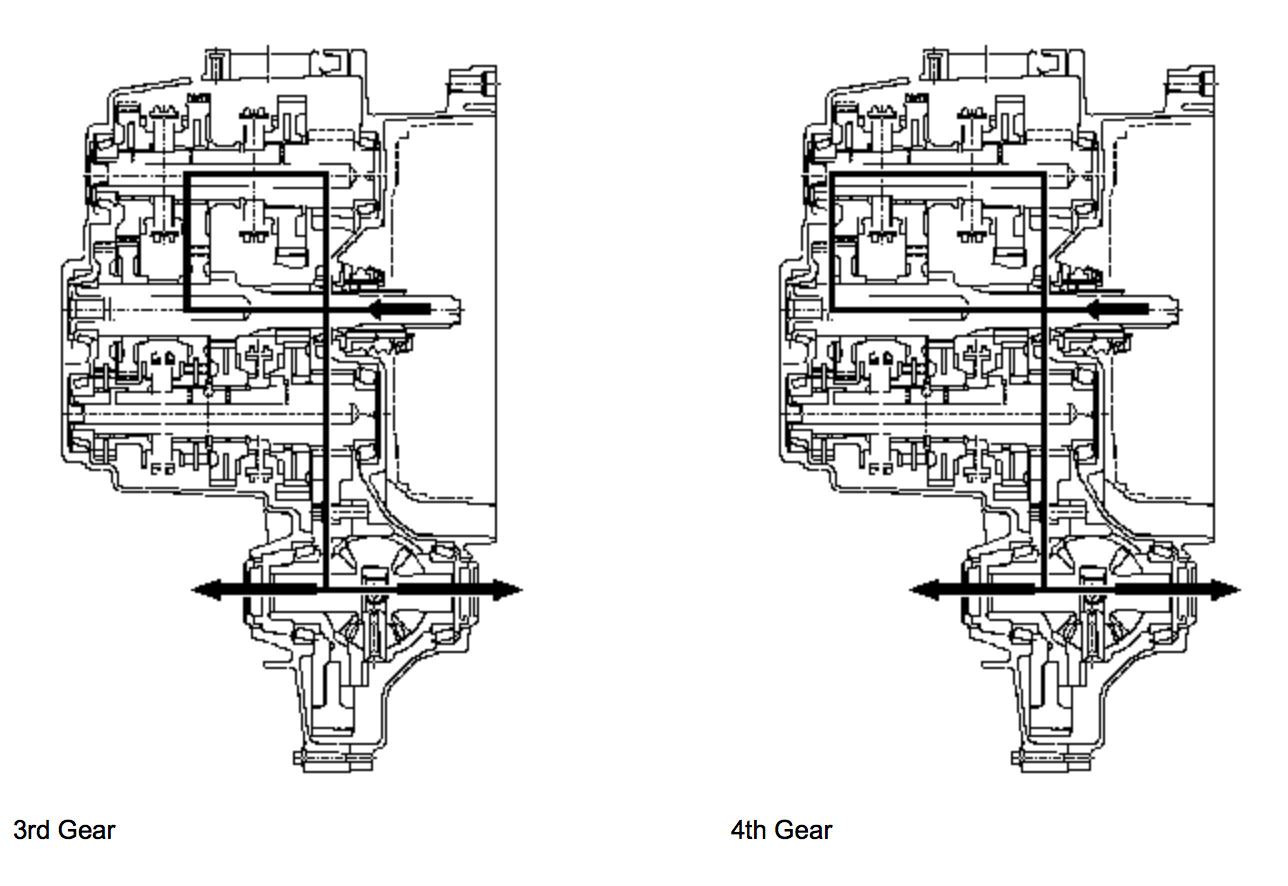

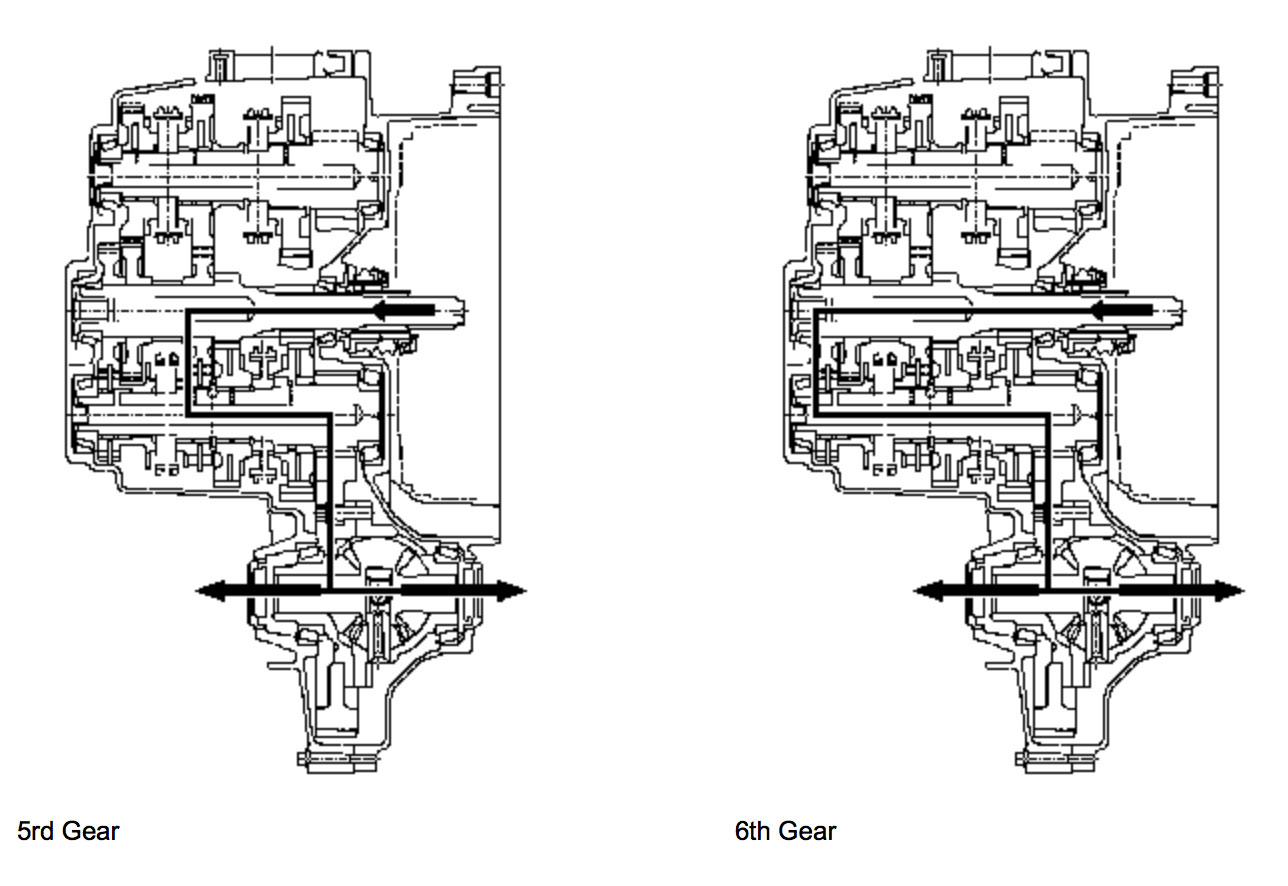

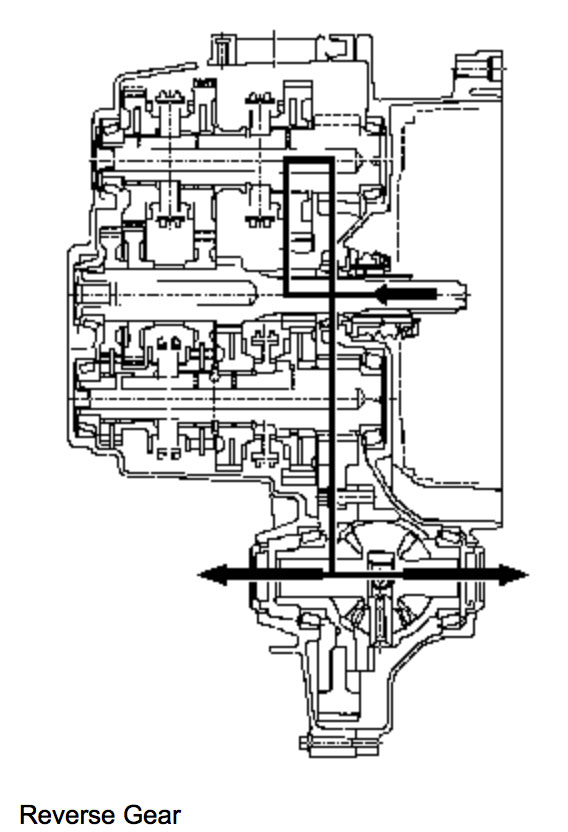

Power flow in the individual gears.

The following diagrams show the flow of power in the individual gears.

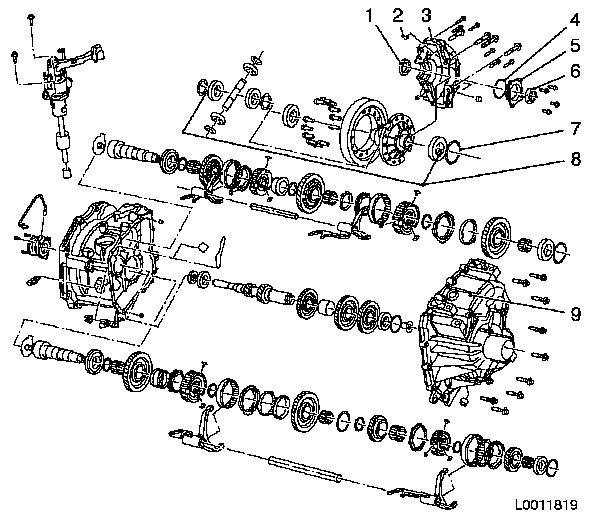

Location of components in the M32 transmission

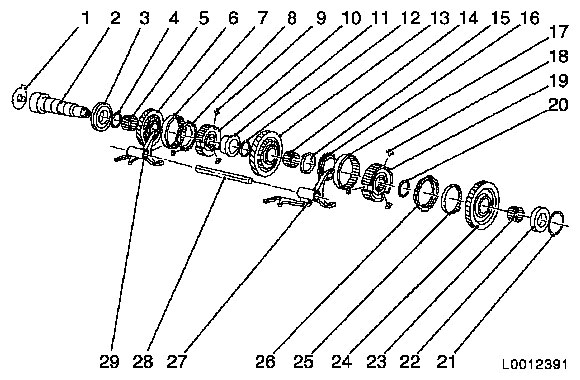

The following exploded diagram shows the location of the components in the M32 manual transmission. The components of the individual shafts will then be described.

- Axle shaft seal ring

- Guide sleeve – differential housing

- Differential housing

- Seal ring – axle shaft seal ring sealing flange

- Axle shaft seal ring sealing flange

- Axle shaft seal ring

- Shim

- Differential assembly

- Transmission housing

- Upper main shaft assembly

- Input shaft assembly

- Lower main shaft assembly

- Clutch bleed connector

- Fastening sleeve

- Reversing light switch

- Central release

- Pressure line

- Clutch housing

- Gearshift assembly

- Magnet

- Oil baffle plate

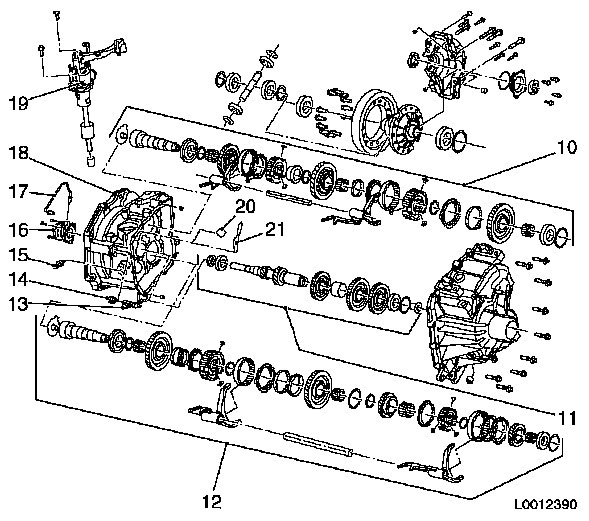

Location of components in upper main shaft assembly

- Fluid collector pipe

- Upper main shaft

- Roller bearing – upper main shaft

- Retaining ring

- Needle roller bearing – reverse gear

- Reverse gear gearwheel (driven)

- Reverse gear shift sleeve

- Synchro ring – reverse gear

- Thrust piece

- Synchroniser body

- Spacer

- Retaining ring

- 3rd gear gearwheel (driven)

- Needle roller bearing – 3rd gear gearwheel

- Intermediate ring

- Synchro ring

- 3rd/4th gear shift sleeve

- Thrust piece

- Synchroniser body

- Retaining ring

- Shim

- Roller bearing – main shaft

- Needle roller bearing – 4th gear gearwheel

- 4th gear gearwheel

- Intermediate ring

- Synchro ring

- 3rd/4th gear shift fork

- Gear shift shaft

- Reverse gear shift fork

Location of components in lower main shaft assembly

- Thrust piece

- Retaining ring

- 1st/2nd gear shift sleeve

- Outer synchro ring

- Intermediate ring

- Inner synchro ring

- 2nd gear gearwheel (driven)

- Needle roller bearing – 2nd gear gearwheel

- Locking ring

- Pressure piece

- 5th gear gearwheel (driven)

- Needle roller bearing – 2nd gear gearwheel

- Synchro ring

- Thrust piece

- Synchroniser body

- Retaining ring

- 5th/6th gear shift sleeve

- Synchro ring

- 6th gear gearwheel (driven)

- Needle roller bearing – 6th gear

- Roller bearing – main shaft

- Shim

- 5th/6th gear shift fork

- Gear shift shaft

- 1st/2nd gear shift fork

- Synchroniser body

- Outer synchro ring

- Intermediate ring

- Inner synchro ring

- 1st gear gearwheel (driven)

- Needle roller bearing – 1st gear gearwheel

- Retaining ring

- Roller bearing – main shaft

- Main shaft

- Fluid collector pipe

Location of components in input shaft assembly

- Input shaft seal ring

- Roller bearing

- Input shaft

- 1st gear gearwheel (driving)

- 2nd gear gearwheel (driving)

- Input shaft bolt

- Shim

- Input shaft bearing

- 6th gear gearwheel (driving)

- 4th gear gearwheel (driving)

- Spacer

- 3rd/5th gear gearwheel (driving)

Synchronisation

An improved synchronisation system, already fitted to the F40 manual transmission, is used on the M32 transmission. The previous sliding blocks and synchro springs have been dispensed with and have been replaced with thrust pieces.

Matched synchronisation systems are also used for the individual gears.

Two and three-cone synchronisation systems are used.

The synchronisation systems used for each respective gear will be shown in the following.

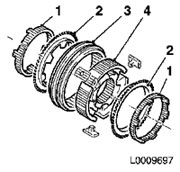

1st/2nd gear

The three-cone synchronisation system is used for these two gears.

- Inner synchro ring

- Intermediate ring

- Outer synchro ring

- Shift sleeve

- Synchroniser body

- Thrust pieces

3rd/4th gear

3rd/4th gear

A two-cone synchronisation system is used for these two gears.

- Intermediate ring

- Synchro ring

- Shift sleeve

- Synchroniser body

5th/6th gear

5th/6th gear

A single-cone synchronisation system is used for these two gears.

- Synchro ring

- Shift sleeve

- Synchroniser body

Reverse gear

Like 5th/6th gear, reverse gear also features a single-cone synchronisation system.

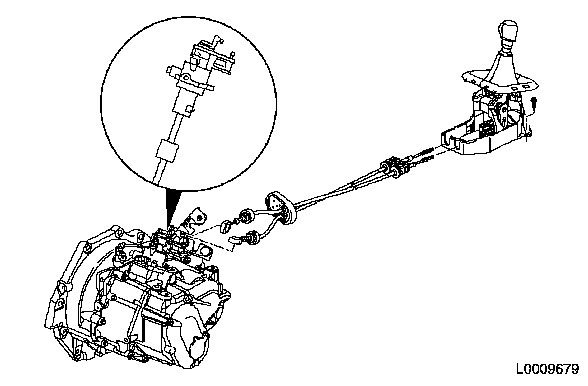

Gearshifting

The M32 manual transmission also has a cable gearshift. The individual gears are selected by means of a central gearshift unit.

Mark for the M32 manual transmission

The mark for the M32 manual transmission consists of a bar code and a combination of numbers.

The mark for the M32 manual transmission consists of a bar code and a combination of numbers.

The letters and numbers located below the bar code have the following meanings:

- M32 Transmission type

- O "Opel" design

- FAM2 Engine family

- 3.941 Ratio

- C Wheel set

- XXXXXXXX Serial number

- NR Transmission code

Transmission fluid

The M32 manual transmission uses the same transmission fluid as the F13 / F17 / F17+ / F23 / F25 / F35 and F40 transmissions.

The transmission's fluid fill quantity is 2.4 litres.

| Container size | Catalogue number | Part number |

| 1 litre SAE 80 | 19 40 768 | 9 120 541 |

| 60 litres SAE 80 | 19 40 710 | 9 194 349 |

Technical data

The maximum input torque for the M32 manual transmission is 320 Nm.

The weight of the M32 manual transmission is approx. 41.5 kg without fluid.

The overall length of the transmission is 329.5 mm.

Transmission ratio

| Engine | Z 20 LEL |

| 1st gear | 3.818 |

| 2nd gear | 2.053 |

| 3rd gear | 1.302 |

| 4th gear | 0.935 |

| 5th gear | 0.744 |

| 6th gear | 0.614 |

| Reverse gear | 3.727 |

| Output ratio | 3.94 |